Cyber-Physical Systems (CPS) are all about self-regulation, and its not just a bunch of sensors and computers cobbled together. No, these are actually sophisticated ecosystems built around a fundamental idea: the Feedback Loop. This loop is what lets the real world tell the cyber world “what’s up”, and then the cyber world does its thing, influencing the real world in return. The result is a smart, responsive system that just works.

What sets cyber-physical systems apart are their distinct characteristics, such as tight integration of cyber and physical elements, real-time operation, adaptability, and advanced networking. These features differentiate CPS from other types of systems.

Getting a handle on the CPS Feedback Loop starts with breaking it down into its three core parts: Sensing, Computing, and Actuation. In CPS, the cyber and physical components are deeply intertwined, enabling real-time feedback, coordination, and responsiveness.

1. Sensing: The System’s Eyes and Ears

First and foremost in any Cyber-Physical System is Sensing where the real world gets converted into something the cyber side can understand. This means taking analog things like temperature, pressure, and movement and turning them into electrical signals that can be fed into the system for analysis.

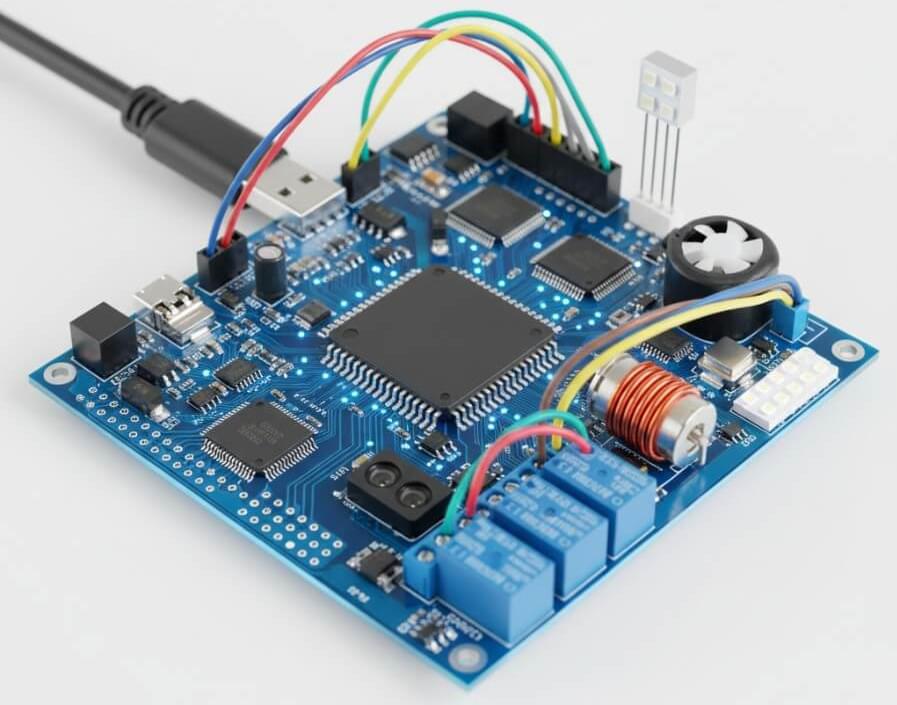

The Role of Sensors: These are the bits that convert what they sense from the physical world into some electrical signal we can measure all sorts of physical stuff with them. Sensors work alongside other devices such as actuators and computational nodes within CPS architectures, highlighting the diverse range of interconnected equipment involved.

Examples: Thermocouples can tell you how hot it is, Accelerometers can measure vibrations or movement, Lidar/Radar lets you figure out where things are and what they look like.

Data Acquisition (DAQ): That raw analog signal from the sensor needs to be cleaned up and converted into a digital format. This usually involves an Analog-to-Digital Converter (ADC) which sticks the continuous electrical voltage into discrete little numbers that the system can use. Feedback mechanisms are fundamental to digital systems, enabling predictable and stable behaviors within CPS.

Why it Matters: The quality of that data is critical, a bad sensor means a bad system.

2. Computing: The “Brain” That Makes Decisions

Once that data is being sensed and digitized, it’s on to the Computing stage, the bit that really makes the system tick. This is where you put all the data through some sort of filter, crunch the numbers, make a decision and work out what to do next.

Software components such as algorithms, control logic, and processing units are integral to this stage, enabling data analysis, automation, and real-time decision-making within cyber-physical systems.

Cyber-physical systems are engineered systems that combine computational elements with physical processes, allowing for autonomous decision-making and real-time control.

A. Where Does All This Processing Happen? Edge vs. Cloud

Where the actual processing happens is a big design choice in Cyber-Physical Systems, it really depends on what kind of system you’re building:

Edge Computing (Microcontrollers and Embedded Systems): This means doing the processing right where the data gets collected, on the device (or “edge”) itself. This usually means using microcontrollers or Single-Board Computers like Arduino or Raspberry Pi.

The big advantage here is that you get super-faster results, that’s critical in real-time control systems like robots or vehicles, and you also don’t need to be stuck on a network.\

Cloud Computing: This means sending that data (raw or pre-processed) over to a remote server (the “cloud”) for serious analysis, storage and machine learning.

The cloud’s got a lot going for it, high-powered computing, data storage, it’s often used for more long-term system optimization (like finding the most energy-efficient way to run things).

The industrial internet leverages both cloud and edge computing to enhance industrial operations within cyber-physical systems, enabling real-time data analysis, automation, and improved efficiency.

B. The Control Logic

At the core of the computing stage is the control algorithm, the bit that makes the “right” decision based on what’s being sensed. The control logic operates as part of a structured feedback system, which continuously monitors and adjusts system behavior in real time. This is where you put simple logic, control theory or even fancy Machine Learning.

Simplified Pseudo-Code (Arduino Example):

Think of a DIY green house CPS system that’s designed to keep the temperature just right:

1 | // 1. SENSING (Input) |

3. Actuation: Turning Decisions into Action

The final stage of this whole self-perpetuating process is Actuation. This is what happens when you take that decision, the result of all the control logic churning away in your cyber world, and turn it back into a physical action that actually starts to change your environment.

The Role of Actuators, in Simple Terms: Actuators are devices that get a signal from the controller and then use it to make something happen, turn a wheel, open a valve, or change the state of something in some way. In industrial cyber-physical systems, actuators are essential for automating and optimizing production processes, enabling real-time adjustments that improve efficiency and flexibility.

Examples You Can Easily Visualise: an electric motor (to turn a wheel, or open a valve) a solenoid (to open or close a fluid path) a heating element (to raise the temperature) or even just a light or LED (to give you a visual cue).

How It All Connects Together: The decision that’s been made is then sent from the microcontroller to an interface circuit, something like a motor driver or relay switch, which then powers or adjusts the signal so that the actuator actually works.

The Continuous Loop: That’s the Magic of CPS

What really gives a Cyber-Physical System its power is the flow of this three-part cycle, over and over again.

The greenhouse cooling fan turns on.

And then the temperature starts to drop.

The sensor picks up on the new temperature right away.

The microcontroller chews over this new data.

It decides the temperature is just right and sends the command to turn the fan off.

And that’s when the fan turns off.

Each cycle represents a feedback response, where the system actively adjusts its actions based on new sensor data.

This seamless process keeps happening, again and again, and it’s what allows the system to keep checking in on the physical world and adjust, without you having to do anything else. That’s what makes it so much more than just a bunch of parts, it’s an intelligent Cyber-Physical System.

Diving Deeper: Real-Time Control with the PID Loop

If basic temperature control is just about using simple if-this-then-that logic, then once you start to get more complex, like when you’re looking at motion, speed or precision, then you need a lot more sophisticated control algorithms. And that’s where the PID (Proportional-Integral-Derivative) Controller comes in, the most common and reliable of all these algorithms, which underpins everything from your car’s cruise control to industrial process control. PID loops are also widely used in quality control to maintain consistency and precision in industrial processes. It’s a great illustration of what real-time CPS can really do.

Case Study: The Self-Balancing Robot

Consider a two-wheeled, self-balancing robot. This is a classic example of a CPS that must execute the feedback loop at lightning speed to prevent falling over.

Sensing: The robot uses a combination of an Accelerometer and a Gyroscope (often bundled in a single Inertial Measurement Unit, or IMU) to precisely measure its current tilt angle and its rate of angular change. This sensed angle represents the Process Variable (PV).

Computing (PID Logic): The robot’s goal is to maintain a target angle (the Set Point (SP)), usually 0∘0∘ (perfectly vertical). The difference between the SP and the PV is the Error (ee). The PID controller calculates the necessary motor correction based on three terms derived from this error:

Proportional §: Calculates a response proportional to the current error. If the robot tilts 10∘10∘, the motor pushes back hard.

Integral (I): Calculates a response based on the accumulation of past errors. This helps eliminate long-term, steady-state errors (drift).

Derivative (D): Calculates a response based on the rate of change of the error. This term predicts future error and damps oscillations, making the response faster and smoother.

The final output is the Control Variable (CV), the exact speed and direction for the motors.

Illustrative Pseudo-Code (Simplified PID Controller):

Extrait de code

1 | // Initialize PID parameters (K constants tuned for the robot) |

Robotics technology, as demonstrated by the self-balancing robot, leads to increased productivity in manufacturing and other sectors by automating tasks, improving efficiency, and reducing human error.

Climate System and Sustainability: Greener Cyber-Physical Systems

Cyber-Physical Systems (CPS) are at the forefront of the fight against climate change, offering powerful tools to make our world more sustainable. By tightly integrating computational elements with physical processes, CPS technologies enable smarter, greener control systems that can help reduce carbon dioxide emissions, boost energy efficiency, and accelerate the shift to renewable energy.

A cornerstone of these systems is the use of feedback mechanisms—especially negative feedback loops—to regulate and optimize physical systems in real time. For example, in smart buildings, sensors constantly monitor environmental conditions like temperature, humidity, and occupancy. The control system then uses this real-time data to adjust heating, cooling, and lighting, ensuring comfort while minimizing energy waste. This kind of negative feedback loop automatically corrects deviations from the desired set point, keeping energy consumption in check and supporting sustainability goals.

Positive feedback can also play a role in climate-focused CPS, particularly when amplifying beneficial outcomes. Take wind farms: by leveraging real time data analysis and machine learning, control systems can dynamically adjust turbine angles and speeds to maximize energy output as wind conditions change. This positive feedback loop helps increase the share of renewables in our energy mix, reducing reliance on fossil fuels and curbing greenhouse gas emissions.

The integration of CPS with the physical environment is essential for achieving large-scale sustainability. By connecting sensors, devices, and other systems through the Internet of Things (IoT), CPS can gather and analyze vast amounts of real time data from the physical world. These feedback systems provide actionable insights for optimizing energy distribution, water usage, and waste management—key areas for reducing our environmental footprint.

In the transportation sector, CPS technologies are transforming how we move. Smart traffic control systems use sensor feedback and control theory to optimize traffic flow, reduce congestion, and lower emissions. Autonomous vehicles, powered by advanced embedded systems and machine learning, can make split-second decisions based on real time data, improving safety and efficiency while supporting the transition to electric and hybrid vehicles.

Building a sustainable future with CPS requires a multidisciplinary approach. Experts in control theory, software development, human factors, and process control must work together to design robust feedback loops and ensure seamless interaction between digital and physical systems. Understanding the complex interplay between computational elements and the physical environment is crucial for developing effective, resilient solutions.

Here are some key areas where CPS is making a real difference in sustainability:

Smart Grids: CPS optimizes energy distribution, predicts demand, and integrates renewable sources, making our power systems more resilient and efficient.

Industrial Processes: Advanced industrial control systems use feedback mechanisms to minimize waste, reduce energy use, and increase productivity in manufacturing.

Transportation Systems: CPS technologies streamline traffic flow, support autonomous vehicles, and encourage cleaner transportation options.

Building Management: Real time monitoring and control of energy, water, and waste in buildings lead to significant resource savings.

Climate Monitoring: CPS enables continuous monitoring of environmental conditions, providing critical data for understanding and responding to global warming.

By harnessing the power of cyber physical feedback systems, we can create more sustainable, adaptive, and efficient infrastructures across various industries. Ongoing research, investment, and collaboration between industry, government, and academia are essential to unlock the full potential of CPS technologies in addressing the urgent challenges of climate change and sustainability.

The Resulting Complexity

This PID loop must execute thousands of times per second (in the millisecond range) to keep the robot balanced. This extreme requirement for low-latency, real-time control showcases why CPS demand specialized hardware and operating systems capable of rapid, deterministic computation at the edge, making it one of the most demanding and sophisticated applications of the sensing-computing-actuation paradigm.

Maintaining compliance with evolving safety and security standards is an ongoing issue in the development and deployment of complex cyber physical systems.