In a world where tech and physical spaces are getting more and more intertwined, a quiet revolution is in full swing, and it’s all about Cyber Physical Systems (CPS) and Physical AI, as NVIDIA CEO Jensen Huang explained during his CES 2026 keynote.

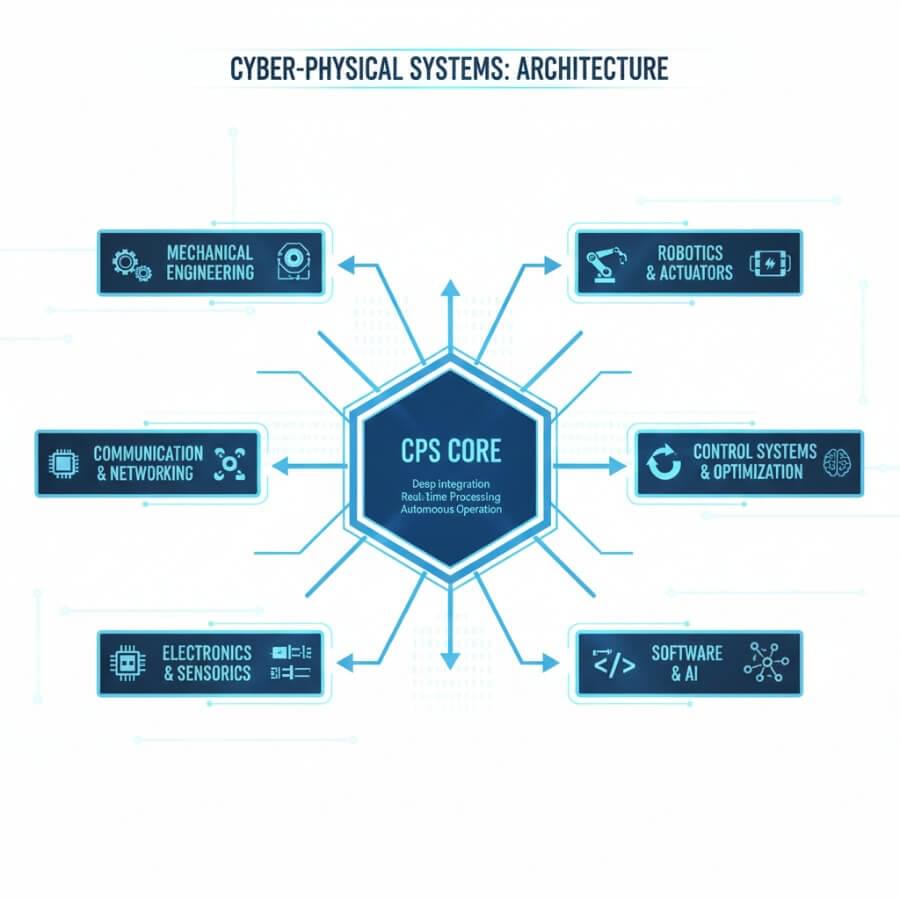

These systems are what happen when you deeply interweave multiple engineering disciplines and what you get is something entirely new and pretty profound. Unlike the simple stuff you might see in embedded systems, CPS are defined by a constant, dynamic give-and-take between the physical world and the digital one. They have the ability to perform complex tasks, perceive their environment, and adapt through advanced technologies such as artificial intelligence and evolutionary algorithms. They’re basically the marriage of machine learning, mechatronics (that’s combining mechanical, electronic and control engineering) and computer science. CPS rely on advanced electronics and the integral role of the electronic system in enabling control, automation, and powertrain applications for getting data through precise sensors; robots and actuators to do something in the real world; robust software and real-time operating systems to handle complex stuff that needs to happen fast; and ubiquitous networking tech (like 5G and industrial Ethernet) to make sure it all happens smoothly and in sync. From the super precise predictive maintenance algorithms that run smart factories to the complex path planning software that guides autonomous vehicles, CPS isn’t just changing tech, it’s fundamentally changing our lives, our industries and our understanding of what’s possible.

What Exactly is a Cyber-Physical System

At the core of all this is a system where the physical and software parts are super intertwined and talking to each other in a coordinated and interactive way. Think of it as a bridge between the physical world all its real key objects and the flow of stuff that’s always happening, and the cyber world, where data flows, computers crunch and communication is the name of the game. CPS is that bridge. Understanding the various aspects of CPS, such as kinematics, dynamics, and control, is crucial for optimizing system performance.

Now let’s try to break it down:

The Physical Bit: This is the bits that gather data from the world around us (temperature, pressure, movement, light etc), and then the bits that do stuff in the physical world (turn a motor, open a valve, turn a light on or off). Actuators perform actions in the real world to complete an assigned task in response to control signals.

The Cyber Bit: This is the computer bit that takes the data gathered, works it out, makes a call and then sends back commands to the physical world to do something. This includes embedded computers, all the networks that make it happen and all the fancy computer algorithms that help it all work.

What really sets CPS apart from regular embedded systems is that constant feedback loop. Data from the world around us gets fed into sensors, gets worked on by the cyber side and then those decisions get sent to the physical side to get something done with an actuator. And that creates a system that is super dynamic, super responsive and often super autonomous.

For example, you can think of an autonomous car. The physical bit includes cameras, lidar, radar and ultrasonic sensors all gathering data all the time, along with the engine, steering and braking, the physical actuators. The cyber side is the super complex software that all that sensor data runs through, sees what’s there, and sends signals back to the actuators to drive the car safely and make sure it doesn’t crash. That constant back and forth is what makes it a CPS.

The Pillars of CPS: Let’s Dive In

To really get CPS, we need to get down to what makes them tick.

- Sensing and Actuation : That’s basically the bridge between the physical and cyber sides.

Sensors : These devices take the physical world and convert it into a format the computers can understand, like a temperature sensor, or an accelerometer. They’re basically the eyes and ears of the system. Sensors detect environmental stimuli and convert them into electrical signals for processing by the system.

Actuators : These take the data from a computer and then do something in the real world, like turn a motor on or off. Actuators are made from various materials, such as metals or elastics, and rely on electrical components to function.

A reliable power supply is essential for CPS, as it ensures all electrical components operate correctly. The flow of electric current from the power supply is what powers robotic systems and enables their functionality.

- Computation and Control : This is basically the brain of the system.

Embedded Systems : Many times the CPS needs a small computer, a “brain”, of sorts in the physical device itself to just get some basic stuff done.

Algorithms : These are the computer programs that take data, make a call and then send that call back to the physical to do something. They can be super simple or super complex, like an advanced Physical AI algorithm.

- Communication and Networking : This is how it all gets talked about, between system components and the outside world.

Wireless Networks : Technologies like 5G, Bluetooth etc that let you skip the cables and get everything talking.

Wired Networks : Ethernet and other wired connections that make sure the systems inside have all the bandwidth they need.

Cloud Computing : Sometimes, the systems need the muscle of a cloud to process all the data.

Data Analytics and Machine Learning : With all the data being pumped out by CPS, we need to be able to get something useful out of it.

Human-Computer Interaction (HCI) : While the systems are super automated, people still need to use them, check on them and set them up. That’s where UI, dashboards and augmented reality come in.

CPS Today: A Landscape of Innovation

Cyber-Physical Systems have finally broken out of research labs and are making their mark on the world. They’re using their innovative might to give quite a few sectors a boost, making life a heck of a lot more efficient, a lot safer, and opening up some entirely new possibilities.

Smart Homes and Cities

In our own homes, CPS shows up as smart thermostats that learn your habits and always seem to find the perfect balance between comfort and saving energy. Smart lighting systems that know when to turn down the lights so they don’t burn out, and security systems that keep a watchful eye and take action when they need to. In the city, CPS is shaping up smart traffic management systems, keeping the traffic flowing, while also helping to reduce congestion. Smart waste management helps the trucks find the most efficient route to take. And intelligent public transport systems get you where you need to go without the frustration.

Sensor networks are constantly monitoring air quality, noise levels, and infrastructure integrity, giving city planners and citizens alike the real-time data they need to make the city a better, more livable place.

Healthcare

In healthcare, CPS are revolutionizing the way we look at patient care. Wearable sensors are tracking vital signs, activity levels and sleep patterns continuously, providing doctors and patients a treasure trove of information to help tackle health problems and keep issues in check before they get out of hand. And with robotic surgery systems, procedures are getting more precise and less invasive by the day. Medical robots are increasingly being used to transport supplies, assist with surgeries, and navigate healthcare environments using AI and sensors, supporting both clinical tasks and the overall efficiency of smart hospitals. Smart hospitals are getting more efficient thanks to CPS, from tracking equipment to managing patient flow and cutting back on excess energy usage.

Telemedicine gets a boost from CPS too, now remote monitoring and consultation are possible, making quality care more accessible than ever.

Industry 4.0 and Smart Manufacturing

The impact of CPS is perhaps most noticeable in the manufacturing world, where it’s giving rise to “industry 4.0.” Factories are turning into “smart factories” where machines, products and systems all work together seamlessly. Robots are increasingly integrated into assembly lines to enhance manufacturing efficiency and productivity. The significance of industrial robotics in modern manufacturing cannot be overstated, as it drives innovation, economic growth, and technological advancement. Sensors embedded in machinery make sure everything is running smoothly, predict when maintenance is going to be needed, and help optimize the production process to the nth degree. A solid understanding of the manufacturing process is essential for designing, controlling, and troubleshooting automated machinery and electronic systems. Robotic systems team up with humans to boost efficiency and safety. The whole supply chain gets a boost, with structured processes ensuring efficiency, precision, and compliance with industry standards, allowing for mass customization and production to become more agile. These advancements enable diverse robot applications across manufacturing, such as the use of series elastic actuators and artificial muscles to enhance safety and functionality.

Transportation and Logistics

Beyond autonomous vehicles, CPS are working to change the entire transportation picture. Smart infrastructure, like car-worn sensors that flag up road conditions, and smart traffic management systems all work to support safe and efficient travel. Logistics networks utilise CPS for real-time tracking of goods, as well as for managing warehouse operations and delivery routes.

Agriculture

“Crop optimization” is just one of the areas where CPS is making waves. Drones and tractors embedded with sensors give farmers a really detailed view of soil conditions, crop health and irrigation needs, and that means they can make some serious adjustments to make their crops grow better, with less waste and less of an environmental impact.

Agricultural robots come in many forms, such as autonomous tractors, drones, and sensor-equipped vehicles, each suited for different tasks. Many robots are specifically designed for tasks like crop monitoring, irrigation, and harvesting, highlighting the diversity and specialization in modern agricultural technology.

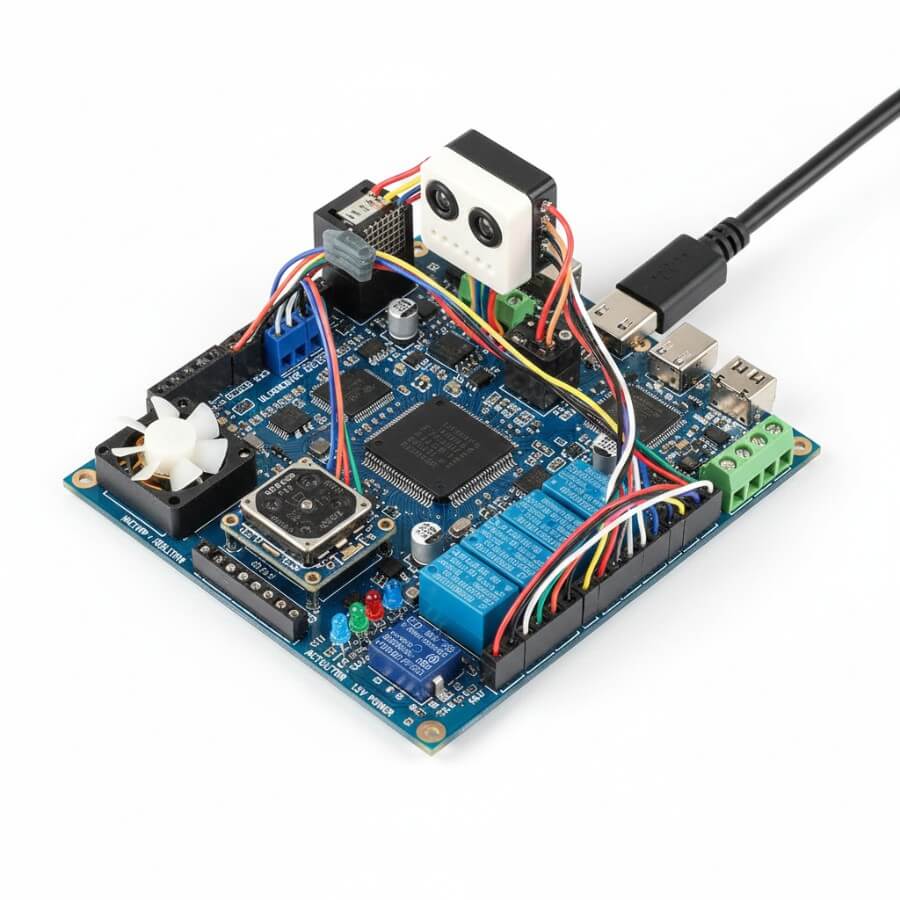

The Building Blocks: Electrical and Digital Components

At the heart of every modern robot, whether it’s an industrial robot assembling cars on a factory floor or a humanoid robot interacting with people, are electrical and digital components working in perfect harmony. These components form the essential backbone of robotics, enabling the precise control and coordination that today’s advanced systems demand. Microcontrollers act as the brains, processing information from a network of sensors that detect everything from movement to temperature, while actuators translate digital commands into real-world actions.

In the world of mechanical engineering, understanding how these electrical systems integrate with mechanical structures is extremely important. Mechatronics engineers specialize in this very integration, blending mechanical, electrical, and control systems to create robots that are not only powerful but also intelligent and adaptable. This multidisciplinary approach is what allows for the development of autonomous robots and collaborative robots that can safely and efficiently work alongside humans in manufacturing environments or even in medical settings.

Embedded systems and digital circuits are the unsung heroes behind the scenes, enabling rapid innovation in robot design. These technologies allow engineers to pack more functionality into smaller, more efficient packages, driving the evolution of robots from simple, pre-programmed machines to sophisticated devices capable of learning and adapting to new tasks. Whether it’s a medical robot performing delicate surgery or a collaborative robot assisting on an assembly line, the seamless integration of electrical and digital components is what makes these advancements possible. As robotics continues to evolve, the synergy between mechanical and electrical engineering will remain at the core of every breakthrough.

Control and Navigation Systems in CPS

Control and navigation systems are the brains and nervous system of Cyber-Physical Systems, empowering robots to perform tasks with remarkable precision and adaptability. In robotics, control systems are responsible for interpreting data from sensors and making real-time decisions that guide a robot’s actions, whether it’s an industrial robot welding parts on a production line or a medical robot assisting in surgery. These systems rely on the principles of control theory and advanced signal processing to ensure that every movement is accurate and every response is timely.

Navigation systems take things a step further, enabling robots to understand and interact with their environment. By integrating data from multiple sensors, these systems allow robots to map their surroundings, avoid obstacles, and plan efficient paths to complete their assigned tasks. This is especially crucial for autonomous robots and social robots, which must operate safely and effectively in dynamic, unpredictable settings.

The development of advanced control and navigation systems is a multidisciplinary effort, bringing together expertise in robotics, electronics, and software engineering. By combining sensors, actuators, and computational elements, engineers create systems that not only perform tasks with greater efficiency but also adapt to new challenges as they arise. As robots become more autonomous and capable, the sophistication of their control and navigation systems will continue to be a driving force behind the next generation of robotics applications.

The Future of CPS: A Glimpse Beyond Today

The applications we see around us now are just the tip of the iceberg. As technology keeps moving ahead, we can expect to see more and more of the cyber and physical worlds combining in some pretty interesting ways. The development of future robots utilizing advanced technologies like artificial muscles, sensors, and artificial intelligence is enabling machines to achieve increasingly human-like capabilities. Many concepts in cyber-physical systems (CPS) and robotics that were once considered science fiction are now becoming reality.

Hyper-Connected and Autonomous Ecosystems

In the future, we can see entire ecosystems of CPS working together in perfect harmony, creating truly autonomous environments. Envision a smart city where traffic lights, public transport and emergency services all know exactly what to do, and where individual cars and even people can get a ride based on what makes the city run best. Or picture a fully autonomous farm where machines do everything from planting to harvesting, all controlled by the same algorithms that adapt to changing conditions every step of the way.

Advanced AI and Machine Learning Integration

The integration of AI and machine learning will become ever more profound in CPS systems, this is what Physical AI is about. This will give us systems that can adapt to new challenges, take proactive action, predict potential problems, and make complex decisions in a highly dynamic world. Self-improving CPS will take data from what they do and use that to get even better and better

Digital Twins and Simulation

The concept of digital twins is set to become more and more mainstream, a digital replica of a physical system, asset or process. Keeping the physical CPS in sync with its digital twin will allow for real-time monitoring, analysis, and simulation of scenarios, helping predict and prevent problems before they happen. We’ll see predictive maintenance, complex system optimization, and even the digital testing of fixes before applying them in the real world.

Human-CPS Collaboration and Augmentation

Some CPS systems will be able to think and act on their own, but most of them will be built to enhance human capabilities. Imagine a world where exoskeletons help you with strength and mobility in the work place, or augmented reality systems that give you real-time information and instruction for tough jobs.

In many collaborative scenarios, human control is essential for supervising or operating CPS, especially in safety-critical applications where manual intervention ensures reliability and safety. Additionally, in social robots, the ability to recognize and interpret human facial expression is crucial for understanding emotions and providing rapid feedback during interactions.

Resilient and Secure Systems

As CPS gets more and more important in the infrastructure of our lives, making sure they’re resilient and secure will be key. Future CPS will need advanced cybersecurity, robust fault tolerance and self-healing capabilities to keep us safe from attacks, system failures and environmental threats. We’ll need to make sure these systems are trusted, and that we can verify they are trustworthy.

Ethical and Societal Considerations

As CPS gets more complex and autonomous, we’re going to need to be having some pretty big discussions about how we use this technology. Questions around accountability, data privacy, impact on jobs, and making sure that access to these technologies is fair will need careful attention and dialogue.

Global Events and the CPS Community

The world of Cyber-Physical Systems and robotics thrives on collaboration, and nowhere is this more evident than at the major international conferences that bring together the brightest minds in the field. Events like the International Conference on Robotics and Automation (ICRA) and the International Conference on Intelligent Robots and Systems (IROS) serve as global hubs for sharing the latest breakthroughs in robotics research, artificial intelligence, and the integration of biological systems with mechanical aspect of engineering.

These international conferences are more than just academic gatherings—they are showcases for the latest industrial robots, humanoid robots, and collaborative robots, as well as the potential power sources that drive them. Industry leaders and startups alike use these platforms to unveil new technologies, from advanced automation solutions for manufacturing to innovative applications in healthcare and transportation. The rapid innovation on display highlights how robotics is transforming industries and shaping the future of work and society.

For professionals in robotics, attending these events is an invaluable opportunity to stay at the forefront of the field, network with peers from around the world, and gain insights into emerging trends and challenges. The exchange of ideas and expertise at these conferences fuels the ongoing development of smarter, more capable robots and systems, ensuring that the global robotics community remains a driving force in the evolution of technology and industry.

DIY CPS: Bringing the Revolution Home

The industrial and urban Cyber Physical Systems(CPS) might seem like they’re out of reach for hobbyists and learners, but thats simply not the case. In reality, the rise of super affordable and ridiculously powerful microcontrollers like the Arduino and Raspberry Pi, combined with open source software and low cost sensors, has really kickstarted a pretty vibrant DIY CPS movement. These projects make for fantastic learning tools and give you hands on experience with the core components of a CPS. Some really cool examples of DIY CPS projects include:

Smart Environmental Monitors: You can build a device that uses a variety of sensors (like a DHT11 for humidity and temperature or PM2.5 sensors for air quality) to collect real time data on its surroundings and then process that data locally on a microcontroller and send the info over to a cloud platform (the “cyber” part) where you can visualise it and get alerts in real time. The system can even turn on a fan or a humidifier based on some pre defined thresholds.

Automated Gardening Systems (Hydroponics/Aquaponics): These systems use sensors to keep an eye on things like soil moisture or water levels and then control pumps (actuators) and LED grow lights based on what the sensors are telling it. This is a pretty cool example of a fully closed loop physical, cyber interaction.

Simple Robotics and Home Automation: There are heaps of projects that see small mobile robots that use ultrasonic sensors to avoid bumping into things and motor drivers to move around, or smart door locks that talk to your phone, and all these examples show the blending of embedded computing and actual physical action. Some DIY robotics projects also use pneumatic actuators powered by compressed air, which is a common and effective way to drive linear motion. In addition to mobile robots, there are many other robots designed for specific tasks in DIY projects, showing the wide range of robotic solutions available.

These projects are super important because they make engineering skills more accessible to everyone, giving people hands on experience with things like embedded programming, sensor integration, real time data processing, and network communication protocols which are all pretty fundamental to how large scale CPS work.

Conclusion

Cyber Physical Systems and Physical AI represent a real paradigm shift, taking us from simple automation to intelligent, interconnected and adaptive systems that actually make sense of the complex world around us. From making our daily lives a bit easier to transforming entire industries, CPS arent just some fleeting tech trend, they’re actually the foundation on which our future is being built. Understanding them isnt just about keeping up with things, it’s about being ready to navigate the increasingly complex cyber physical landscape that is unfolding right before our eyes. The journey has just started, and the possibilities are limitless.